![]()

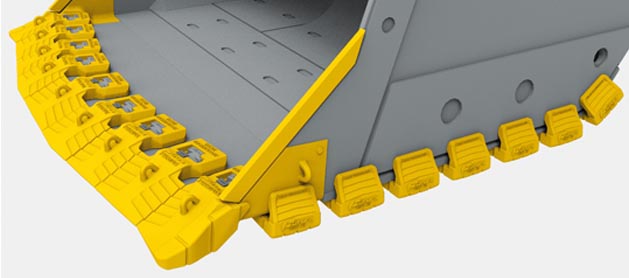

Help maintain the profile of the bucket

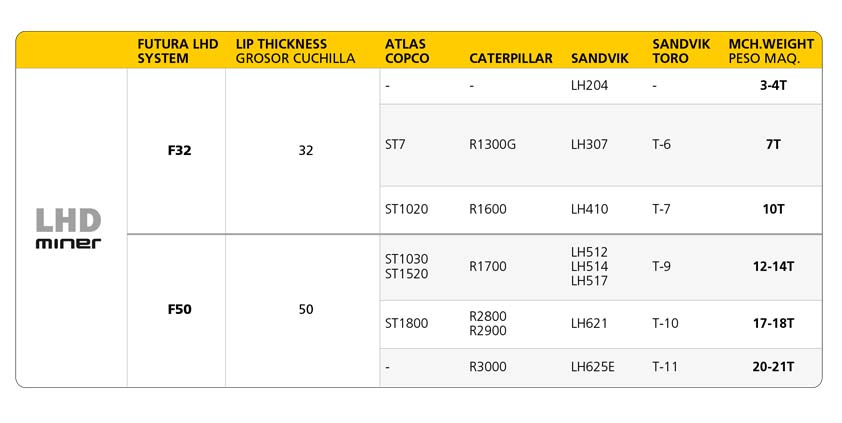

FUTURA LHD PRODUCT RANGE

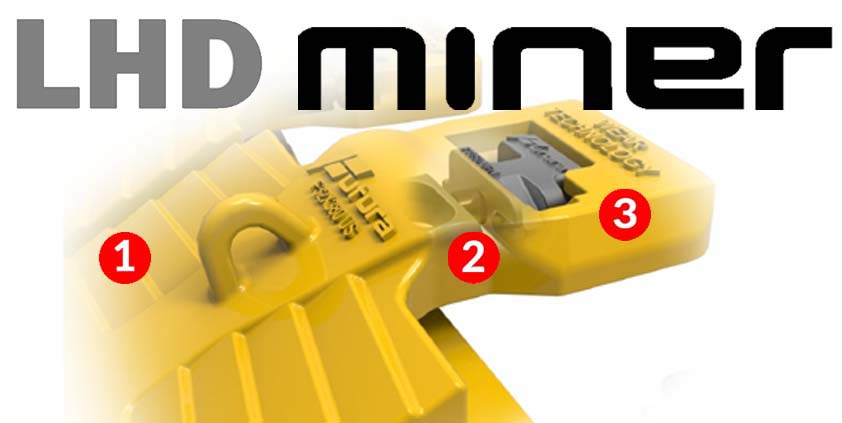

compatible with Esco Posilok

![]()

Piston expansion

![]() Maintains pin tension

Maintains pin tension

Technical

Features

LHD Miner – 20mm. The 20mm. Piston Expansion allows to maintain tension of the shroud against the blade throught out the shroud wear life.

3/4 Shroud UCLH UCRH Corners are shorter to help maintain bucket profile when the rest of shrouds are worn.

LHD MINING engineered parts are quick and easy to replace.

Full range of teeth, adapters and pins guarantee a suitable part for your excavator or loader mining bucket.

LHD Blades are custom made blades for underground mining.

Benefits

Raised central ribs, lateral ribs and recessed pocket help material flow and significantly extend tooth wear life.

Self-sharpening design:

Innovative solutions and engineered design– Thanks to its optimal design more than 68% of steel has been used without losing teeth sharpness. The LHD MINING range has approximately 20% more usable wear material than other systems.

Range

Part Sizes

Guide to part sizes by MAXIMUM MACHINE WEIGHT (TONS)

Parts at

Work